Predicting the temperature of a shipment is complicated, but it doesn’t have to be. Most logistics planning looks at the high and low temperatures at the origin and destination. But that leaves out the real story: what happens in between. A truck leaving Denver in 45°F weather and arriving in Dallas at 85°F doesn’t actually experience a neat temperature flip: it runs the gauntlet of plains sun, high-altitude nights, and highway rest stops.

Here’s the kicker: beer doesn’t heat up or cool down instantly. Cargo takes time to absorb and release heat. That lag works in your favor. With the right data, you can know whether a six-hour stretch of cool nighttime air will protect your product, even if the final destination is hot.

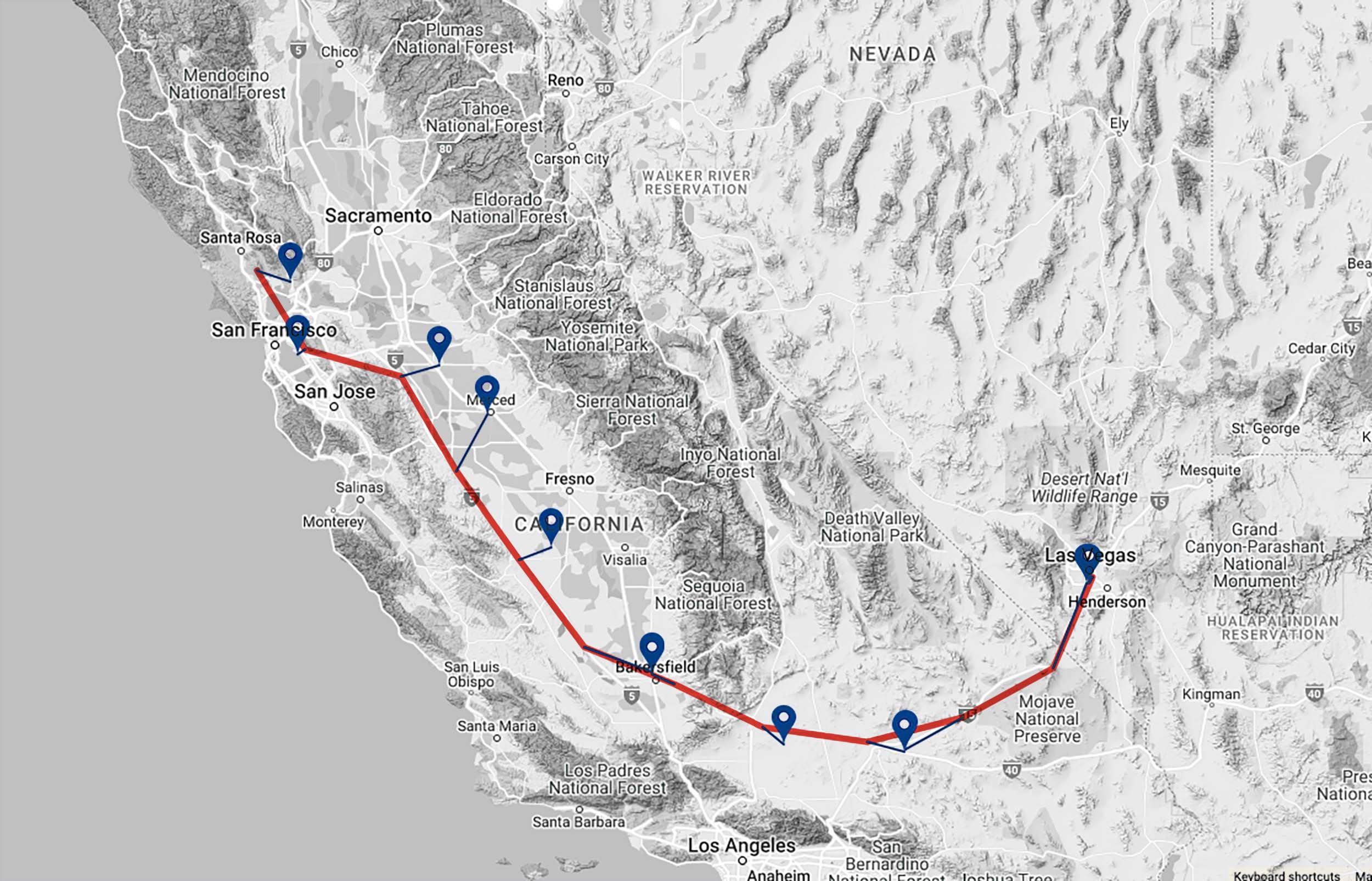

CoolShip simulates beer temperature along the specific route your truck will travel. That means factoring in real-world truck speeds, mandatory rest times, and the shifting weather along every leg. The result: a more accurate picture of when your shipment really needs a reefer, and when it doesn’t.

Our models, validated against real shipment data, show that you often don’t need refrigeration for stretches of the year when common sense would say otherwise. But that pattern changes by season, geography, and lane. A shipment that’s fine dry in April might need cooling in August

Reefers are expensive. They’re also carbon-intensive. Honing in on exactly when refrigeration is truly necessary reduces both costs and emissions while ensuring the beer arrives tasting as it should. For CFOs and COOs, that means protecting margins without taking on risk.

This is just the start. In future Lab Notes, we’ll dig into how our beer-temperature model works and why empirical validation matters. And if you want to see how conditions are changing week to week and how COOs can use CoolShip to stay ahead of reefer–dry price spreads, keep an eye on our Route Notes.

Stop paying for cold air when you don’t need it. Run your first route with CoolShip and see the difference.

Leave a Reply