Fall’s shoulder season mixes winter nights with lingering summer days. Freezing mornings up north and lingering heat down south create a narrow window for cost savings through dry shipment if you know where to look.

This week, U.S. conditions are split. Northern plains and the Northeast see sub-freezing mornings, while southern routes hit the 80s during the day. Transitional weeks like this often lead teams to overuse reefers, just to be safe.

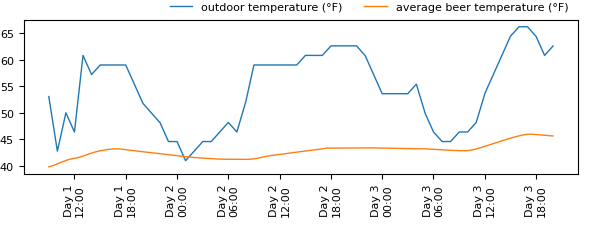

Simulations show there’s more flexibility than it looks. Seattle-to-Chicago and Asheville-to-Denver shipments stay in the safe 40s, thanks to beer’s thermal mass and moderate daytime highs. Even as temperatures swing outside, product stability holds.

Meanwhile, lanes like San Diego-to-Dallas still need refrigeration. CoolShip identifies which lanes can safely run dry, so teams don’t pay for unnecessary reefer coverage.

For logistics leaders, shoulder season is a moment to cut costs without risking product. Lane-level thermal modeling shows exactly when reefers are required, helping companies save money, reduce carbon emissions, and avoid blanket assumptions that drive unnecessary spend.

As cold-season patterns develop, we’ll continue monitoring which lanes need refrigeration and which can still run dry. Keep an eye on upcoming Route Notes to stay ahead of the shifting map.

See how your routes perform under real-world temperature forecasts. Run a lane in CoolShip.

Leave a Reply