A temperature model that isn’t tested in the field is just theory. At CoolShip, we prefer proof.

Predicting beer temperature might sound like a guessing game, but it’s not. It’s physics, data, and math, all working together to describe how a shipment really behaves on the road. Beer responds to heat in complex ways, and the air inside a trailer doesn’t behave like a tidy lab environment. That’s why we built CoolShip’s validation around the real world.

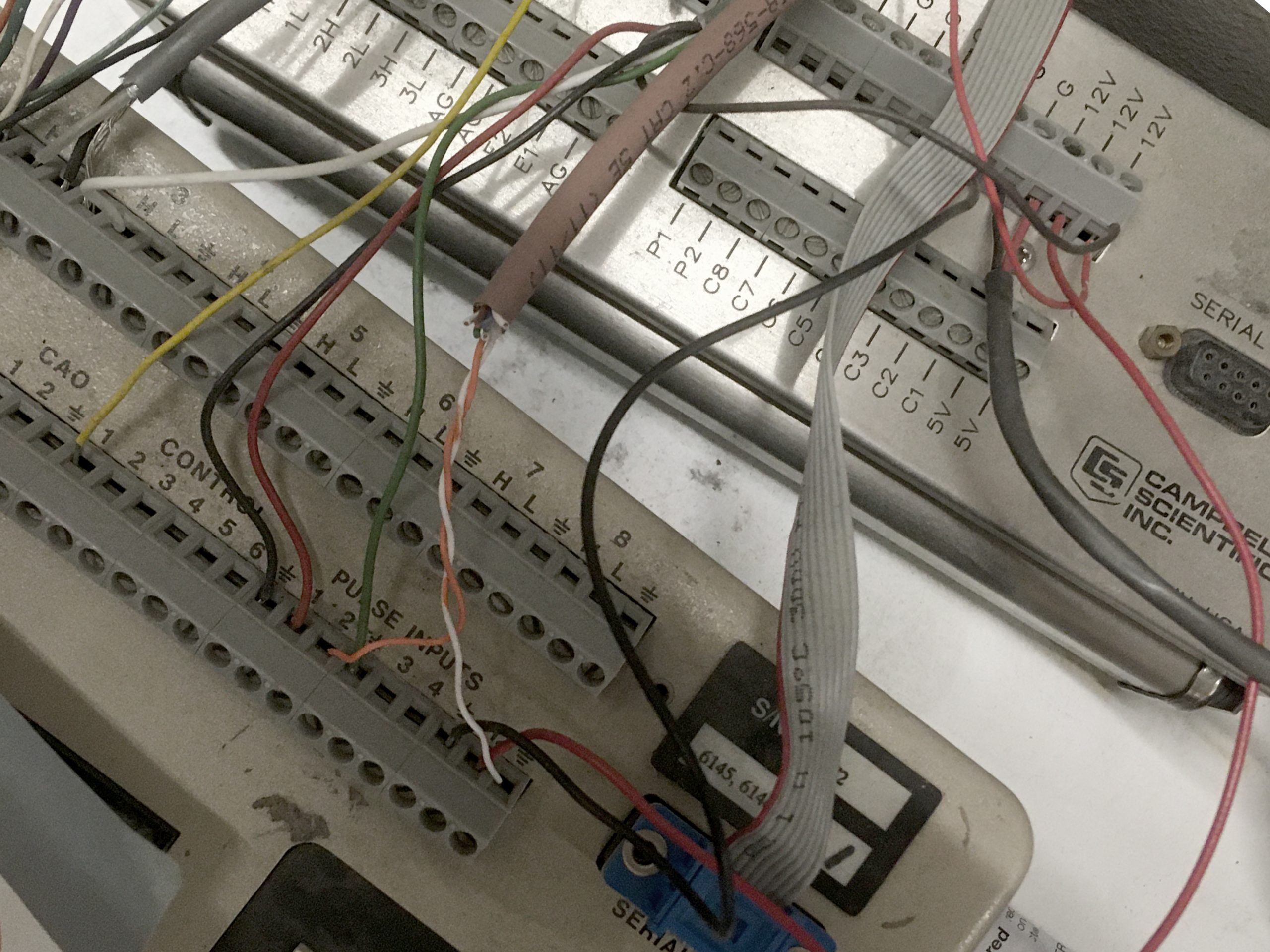

Our team measured what actually happens inside the truck. We strategically placed temperature sensors and ran test shipments through a range of weather conditions. Those probes told us what no spreadsheet can: how quickly beer actually warms or cools, how the truck responds to varying weather conditions, and which temperature swings matter.

Then we compared that field data against CoolShip’s predictions. The results were remarkably close. That tight alignment between forecast and measurement gave our brewers and logistics partners the confidence to use CoolShip in live operations — not as an experiment, but as a trusted part of their decision-making.

For CFOs and COOs, that validation is the difference between theory and risk control. It means you can look at CoolShip’s recommendations and know they’re grounded in data collected on real trucks, moving real beer. That produces savings: not by trimming safeguards, but by reducing the uncertainty that drives unnecessary refrigeration costs.

We’ll be posting more Lab Notes on our methods and continuing to track real-world routes in our Route Notes series. Together they show how CoolShip keeps refining its model as conditions and shipping patterns change.

If you’d like to see how our validated temperature model performs on your lanes, get in touch.

Leave a Reply